detail

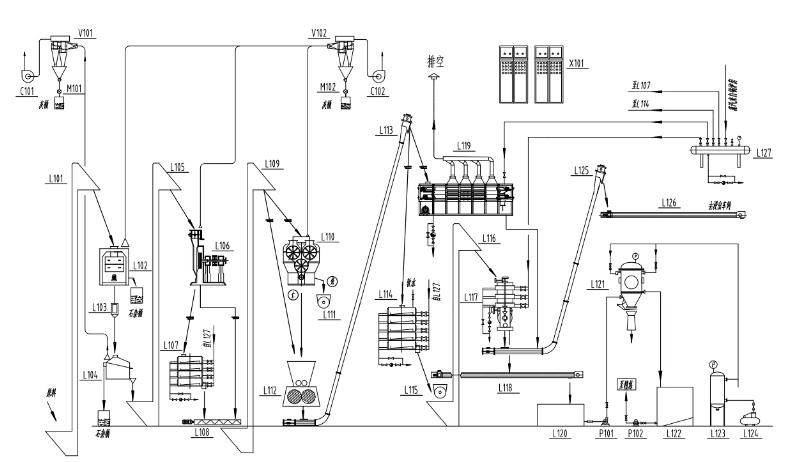

1. The Sunflower Oil Production Process Machine Process:

Sunflower seed---Magnetic separation---Cleaning ---Crushing---Flaking---Pressing-To Extraction Process:

? Different combinations of process can process various oil plants in one workshop.

? Use special intensified pretreatment technology for aroma sunflower seed oil to make it more aroma.

? Adopt advanced and reliable shelling technology to meet higher requirements for protein content in meal.

? Extrusion treatment is used for raw materials with hard extraction, large-sized powder, and large capacity, which can reduce residual oil and solvent consumption, and increase the capacity by 50-80%.

? The new technology of shelling and low-temperature treatment can ensure high protein and least denaturation.

2. Every equipment introduction:

? Feeding pot: storage the material

? Bucket elevator:transfer the material.

? Cleaning?sieve:get?rid?of?big?impurities.

? Gravity stone separator:get rid of some heavy impurity..

? Magnetic separator:get rid of some metal impurity

? Flaker:Make the material into the thickness of 0.25 mm to 0.35 mm,Damage material‘s cell walls as far as possible, make it easy to get grease from material’s cell, in addition, the material press into slices, increase the surface area of the embryo, ensure the effect of embryo steaming and frying, and shorten the path from grease to embryo .

? Softening pot:Damage material’s cell and easy to get oil,improve the quality of oil.

? Oil press machine:to get crude oil.

? Oil clarifying tank:to storage clean oil.

? Plate and frame filter:filter the impurities from oil.

3. Specification

|

Power consumption |

36KWH / t |

|

Steam consumption |

280 kg / t |

|

Pre-pressed cake thicknes |

≤17mm |

|

Pre-pressed cake moisture |

≤4-6% |

|

Pre-pressed Residual oil |

≤14-16% |