detail

1. Refining Processes:

Get the high-grade cooking oil from crude oil through the hydration degumming, continuous decoloring, filtering, continuous deacidifying and deodorizing 4 main sections. It’s a flexible process, economic and environmental protective.

? Decolour tank is for bleaching grease.

? Deodorizing tank is for desdorizing grease(stainless steel).

? Conducting oil furnace provide thermal enery need for production, the temperature reach to 280degree.

? Vacuum pump provides vacuum for bleaching, deodorization which can reach 755mmHg or more;

? Air compreassor can dry the bleached clay

? Air press is for filter clay

? Steam generator can generate steam distillation required.

This kind of oil refining eqiupment make the oi reach the standard level national edible oil.

2. Edible oil refining/refinery manufacturer Characteristics:

? Safety:

1) We use auto welding machine to make the reactor, which can quarrantee the quality of welding seam, avoid cracking and has a long life for about 8 years.

2) Professional heating treatment and x-ray detection chamber for welding seam .

3) Vacuum system to prevent oil gas be back to reactor causing accident.

4) With professional thermometer , professiona pressure gauge and safety valve.

? Environment friendly:

1) Dedusting system to prevent gas and dust from coal burning

2) The exhaust gas will be recycled for heating reactor ,no gas pollution

3) Well sealing on every junction parts to prevent gas leak,no smelly

? Longer service life :

Using Q345R special steel plate ,welding seam with auto welding an will get heating treatment and x-ray detection to extend the life of reactor to the most extend, and the life will 8 years.

? Energy saving:

1) Well sealing for heating system ,no gas leak and saving fuel.

2) The exhaust gas will be recycled for reactor heating.

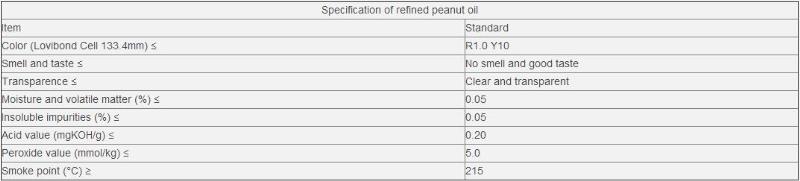

3.Specification: