detail

Project Details

Performance introduction:

1. The machine can be used to dry rice, wheat, corn, soybean, sorghum, barley, sesame and other grains with high moisture content, and is suitable for farms, grain stations and grain growers.

2. Energy saving drying technology is adopted to automatically adjust drying temperature and time, reduce thermal shock, reduce noise and vibration compared with similar products, save gas, coal and electricity, and have a long service life.

3. The automatic monitoring and protection grain instrument device is set to automatically monitor and control the slant position, grain temperature, air temperature and the operation of supporting auxiliary machines during operation, so as to ensure normal and safe production.

4. Natural gas, biological particles and coal are used as fuels, which are converted into clean hot air by heat exchanger, and do not pollute grains.

5. The equipment has simple structure, small investment, low operation cost, convenient operation and maintenance.

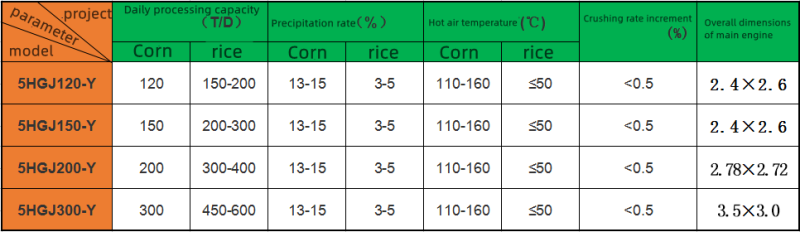

Technical parameters:

Product advantages:

1. The drying system adopts a special reversing structure, with smooth air intake, no dead angle and even drying.

2. It has the functions of control, monitoring, alarm, etc. It can realize the one-time drying of raw grains with more than 30% moisture to 14% safe moisture, with high automation, reliable performance, and high drying efficiency.

3. Four blade wheel volumetric discharger and frequency conversion speed regulation are adopted to ensure uniform grain moisture after drying.

4. The tower body is made of galvanized sheet, which will never rust. The material is thick, the structure is solid, the failure rate is low, and the service life is long.

5. Adopt environment-friendly energy-saving hot air stove, with high thermal efficiency and low drying cost.

6. The drying process is long, the mixing is even, and the grain quality after drying is good.